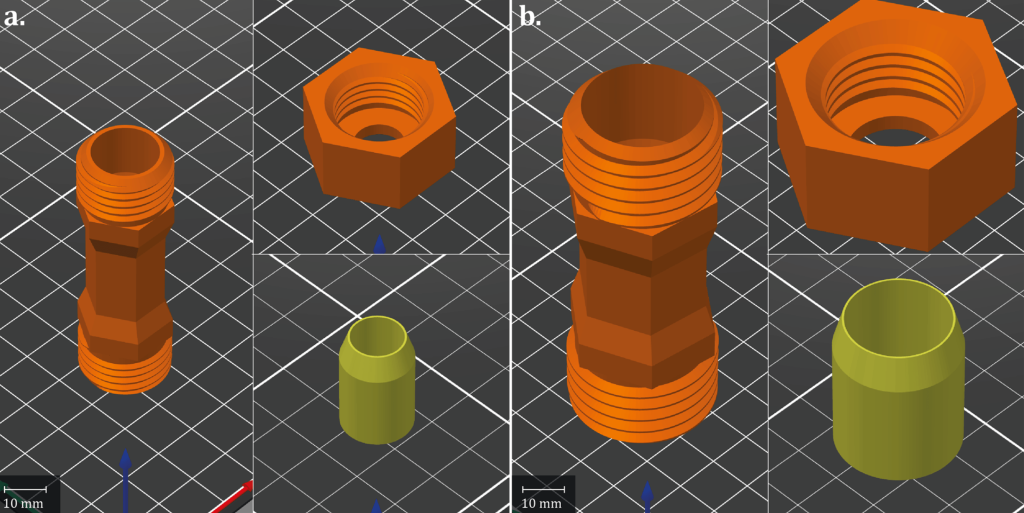

Could be promising as long as the print is water tight.

The researchers believe using a parametric-driven method for local, on-demand 3D printing of customized fittings will unlock more efficient water management.

there’s a whole lot of buzzwords there. if the current system can’t be fixed becuse there’s no parts (pipe fitting, and pipes,) to replace the leaky bits, then how exactly do you expect them to source a 3 d printer and filament? More to the point… FDM prints themselves are prone to leaking, from a myriad of issues.

I don’t think 3d printing the pipe fittings is the answer here.

that said, it’s cool and fun all the same.

Yeah we’re not talking about a BambuLabs printer with some PLA here.

I would love some extra micro plastics in my water.

3D Printed pipe fittings have to be one of the worst 3D printing applications I’ve ever heard of. We use metal fittings for a reason.

Plenty of plumbing is done with moulded plastic pipes and fittings, and I’ve 3D printed garden hose fittings (things like GHT to BSP adapters, which aren’t easy to buy) with success, so it’s not like moulding is the only way to make plastic good enough.

If these weren’t made using the FDM process, they could be quite useful; but as-is the FDM process is weak along the Z axis, and these kinds of fittings aren’t going to withstand a lifetime of abuse – not only that, the kinds of plastics we’re printing with aren’t really regulated to any kind of degree, so depending on what kind of things are in the water, you could just be pumping large amounts of microplastics into your system by using something like this.

It’s a great avenue for research, but we need more robust methods of printing for something like this.